Definition…

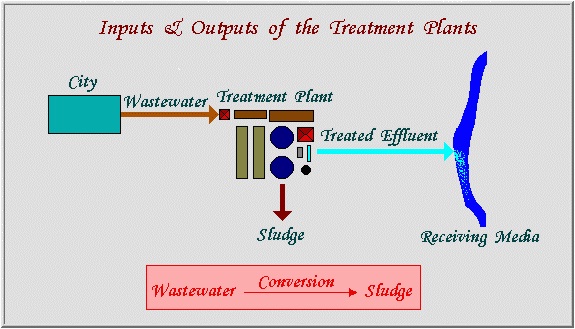

Wastewater treatment objectives are accomplished by concentrating impurities into solid form and then separating these solids from the bulk liquid. These concentration of solids, referred to as sludge, contains many objectionable materials and must be disposed of properly. The sludge resulting from wastewater treatment operations and process is usually in the form of a liquid or semisolid liquid that typically contains from 0.25 to 12 % solids by weight, depending on the operations and processes used. Of the constituents removed by treatment, sludge is by far the largest in volume, and its processing and disposal is perhaps the most complex problem facing the engineer in the field of wastewater treatment.

Sludge disposal facilities usually represent 40 to 60 % of the construction cost of wastewater treatment plants, account for as much as 50 % of the operating cost, and are the cause of a disproportionate share of operating difficulties.

Characteristics…

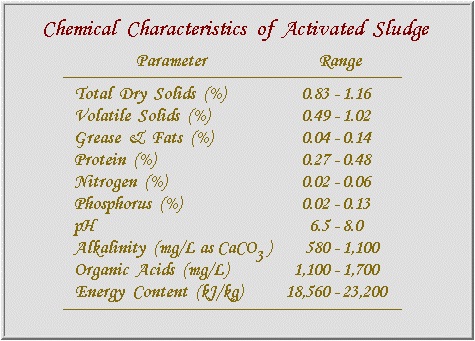

Typical data on the chemical composition of activated sludge is shown below. Many of the chemical constituents are important in considering the ultimate disposal of the processed sludge and the liquid removed from the sludge during processing.

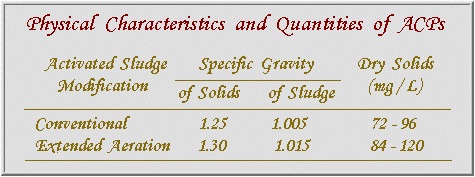

Data on the quantities of sludge produced from conventional and extended aeration activated sludge processes are shown below.

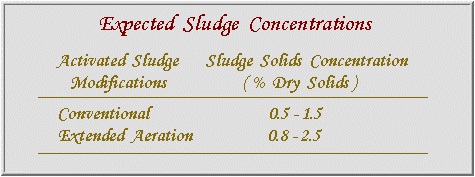

Corresponding data on the sludge concentrations to be expected from various processes are shown below.

Flow Diagrams for Sludge – Processing…

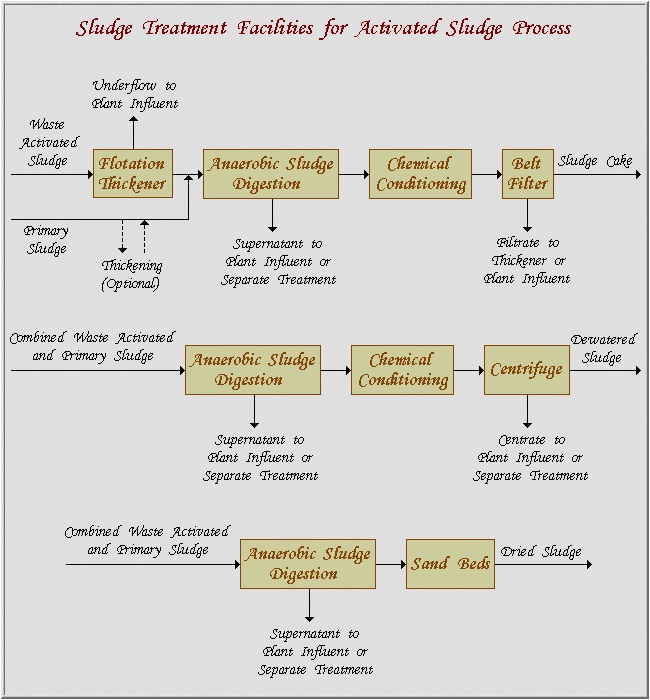

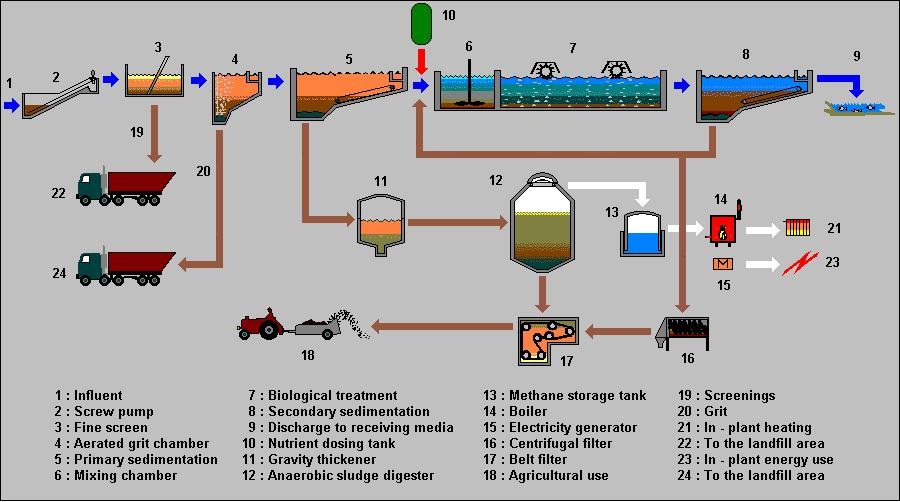

In practice, the most commonly used process flow diagrams for sludge treatment may be divided into two general categories, depending on whether or not biological treatment is involved. Typical flow diagrams incorporating biological processing are presented below.

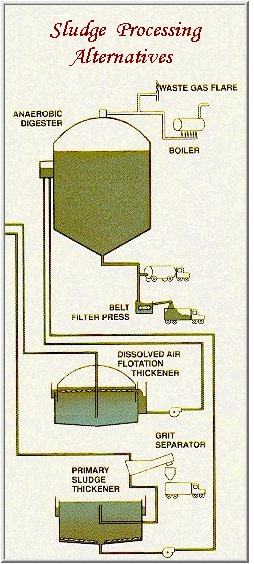

Most Commonly Used Alternatives…

Depending on the source of the sludge, thickeners may be used contingent upon the method of sludge stabilization, dewatering, and disposal. Following biological digestion, any of the several methods shown may be used to dewater the sludge, the choice influenced by economic evaluations and local conditions. Because the presence of industrial and other toxic wastes has presented problems in the operation of biological digesters, a number of plants have been designed with other means for sludge treatment.

Sludge Thickening…

Gravity Thickening…

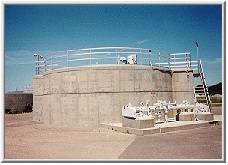

Gravity thickening is accomplished in a tank similar in design to a conventional sedimentation tank. Normally, a circular tank is used. Dilute sludge is fed to a center – feed well. The feed sludge is allowed to settle and compact, and the thickened sludge is withdrawn from the bottom of the tank. Conventional sludge – collecting mechanisms with deep trusses or vertical pickets are used to stir the sludge gently, thereby opening up channels for water to escape and promoting densification.

The supernatant flow that results is returned to the primary settling tank or to the headworks of the treatment plant. The thickened sludge that collects on the bottom of the tank is pumped to the digesters or dewatering equipment as required; thus, storage space must be provided for the sludge. Gravity thickening is most effective on primary sludge. A photo of gravity thickener is shown below.

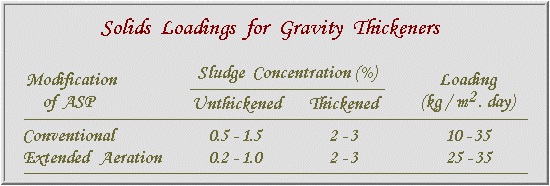

Gravity thickeners used dewatering the treatment sludge are designed on the basis of solids loading. To maintain aerobic conditions in gravity thickeners, provisions should be made for adding 24 to 30 m3/m2.day of final effluent to the thickening tank. Typical concentrations of unthickened and thickened sludges and solids loadings for gravity thickener are shown below.

An operating variable, sludge volume ratio normally range between 0.5 and 20 day; the lower values are required during warm weather. For operation, alternatively, sludge – blanket depth should be measured. Blanket depths may range from 0.6 to 2.4 m; shallower depths are maintained in the warmer months.

Flotation Thickening…

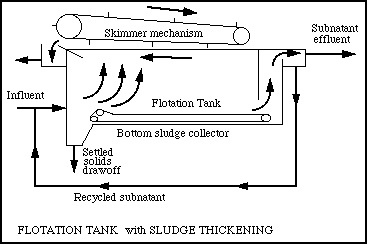

There are three basic variations of the flotation thickening operation ; dissolved – air flotation (DAF), vacuum flotation, and dispersed – air flotation. Dissolved – air flotation is being widely preferred for especially waste activated sludge. Air is introduced into a solution that is being held at an elevated pressure. When the solution is depressurized, the dissolved air is released as finely divided bubbles carrying the sludge to the top, where it is removed. Photos of DAF are shown below.

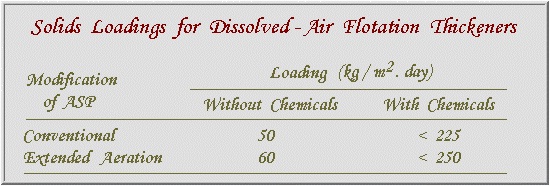

Higher loadings can be used with flotation thickeners than are permissible with gravity thickeners because of the rapid separation of solids from the wastewater. Typical solids loadings for DAF units are shown below.

Source: web.deu.edu.tr